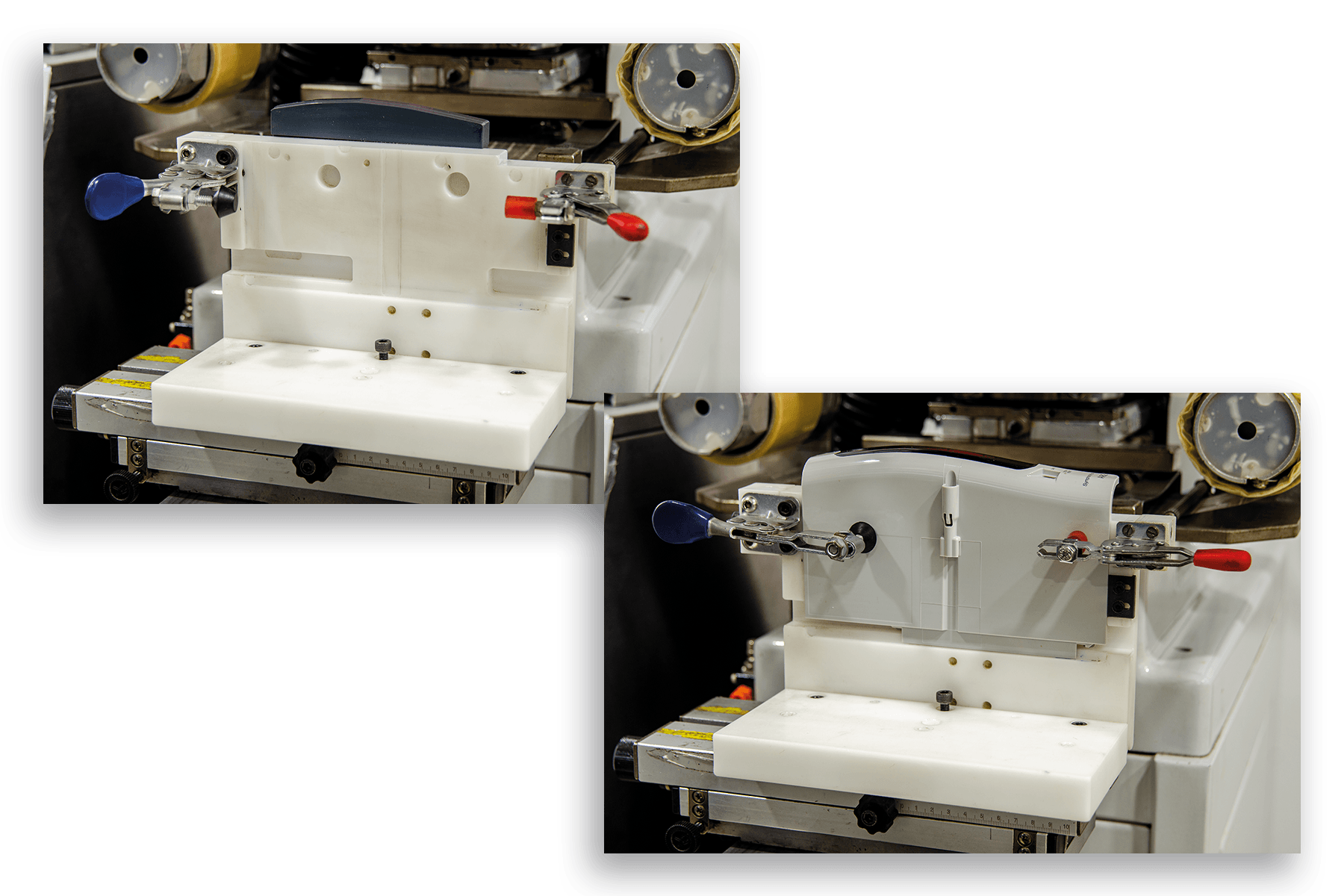

Stamping and forming tools play an important role in the manufacturing process of many products. With shorter product life cycles and demand for shorter time to market for new products, designing and manufacturing of stamping and forming tools becomes more important in the manufacturing industry.

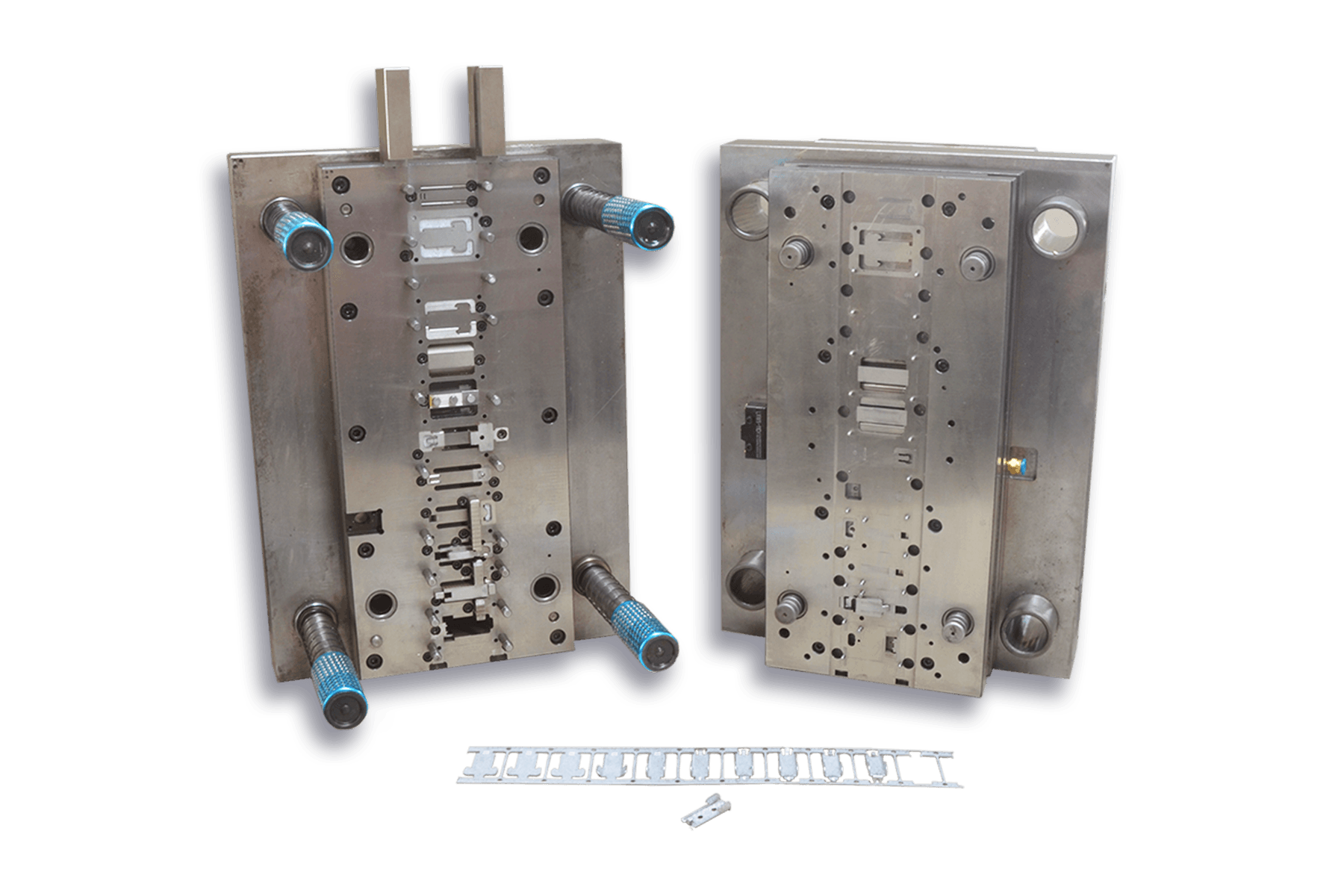

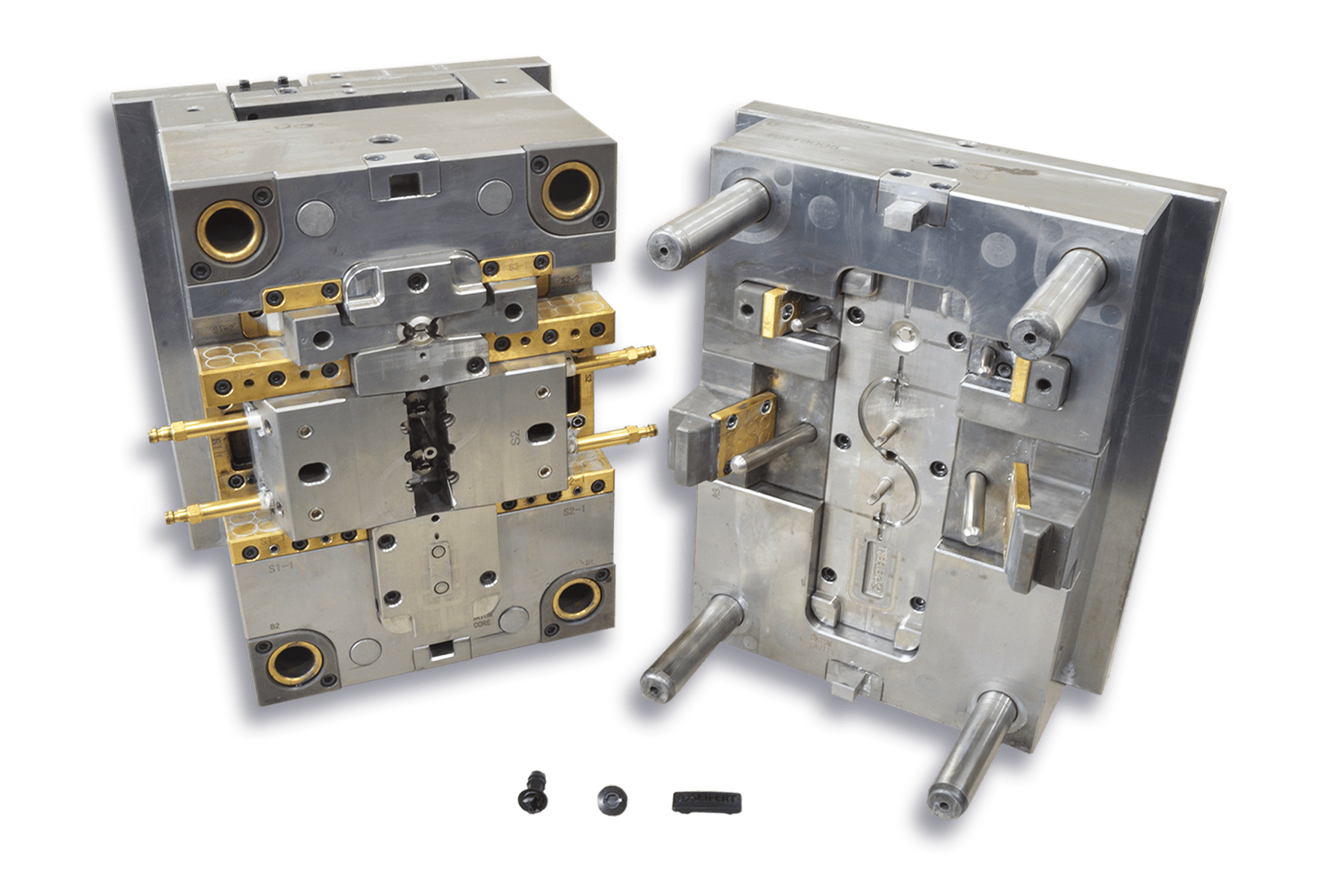

The choice of metal stamping materials used depends on the desired attributes of the finished piece. Ranging from simple stamping items, such as metal clips, springs, weights, washers, and brackets to more complex designs, we at Matotech have the knowledge, experience and craftsmanship to design and manufacture the tools you need.